for about a year i have been making my own PCB's by using toner transfer methods. i have been able to make some pretty nice boards with very good results with all kinds of substrates; i have used plain paper, glossy junk mailer/magazine pages, and commercial transfer paper. the results have been very strong using the transfer paper, a dextrin coated sheet that the Laserjet easily prints to.i have been using the household iron method to remelt the toner to the board (simply put print side to copper and apply heat and pressure). i have found you need to be careful, because you can smear the molten toner. to solve this i have adapted a technique from the PulasFX forums where you use a hardwood dowel to roll the board between the iron and dowel. the action takes a little to master but it does quite well, i also bought a rolling pin and will sometimes go to Printmaking and roll right on top of the department hotplate.

for about a year i have been making my own PCB's by using toner transfer methods. i have been able to make some pretty nice boards with very good results with all kinds of substrates; i have used plain paper, glossy junk mailer/magazine pages, and commercial transfer paper. the results have been very strong using the transfer paper, a dextrin coated sheet that the Laserjet easily prints to.i have been using the household iron method to remelt the toner to the board (simply put print side to copper and apply heat and pressure). i have found you need to be careful, because you can smear the molten toner. to solve this i have adapted a technique from the PulasFX forums where you use a hardwood dowel to roll the board between the iron and dowel. the action takes a little to master but it does quite well, i also bought a rolling pin and will sometimes go to Printmaking and roll right on top of the department hotplate.

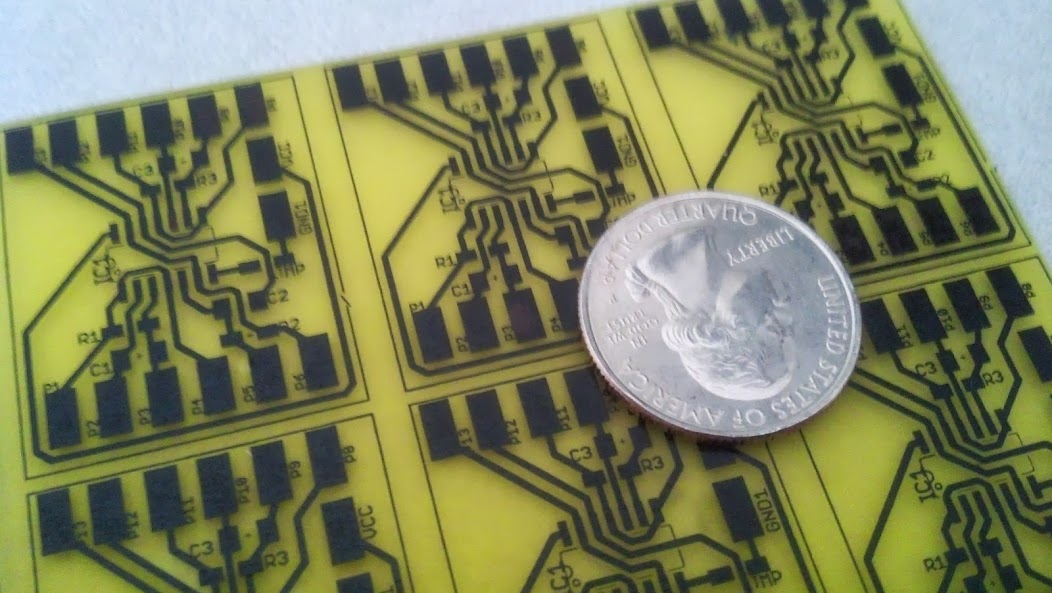

the big improvement is a new laminating machine to assist with the toner transfer methods for making resists for my PCB's. i still use the iron to tack the transfer to the board but now the heavy lifting (pressing) is done with the laminator with a few caveats, the machine will grudgingly accept 1.6mm (1/16in) inch boards but i do not recommend it. the .8mm (1/32) boards do very well and last Thursday, i was able to fabricate some SMT plans with .275mm traces. i still have some smearing (i need practice on the number of passes in the laminator), but they look really awesome otherwise.

No comments:

Post a Comment